Hi, it’s been way too long of a time. It’s time for an update.

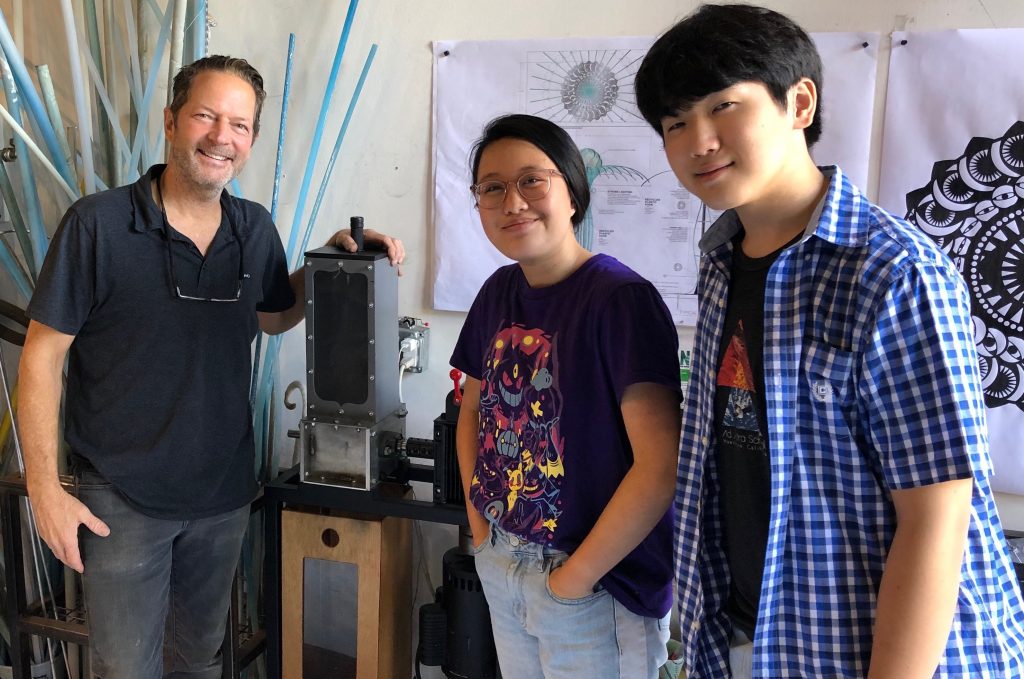

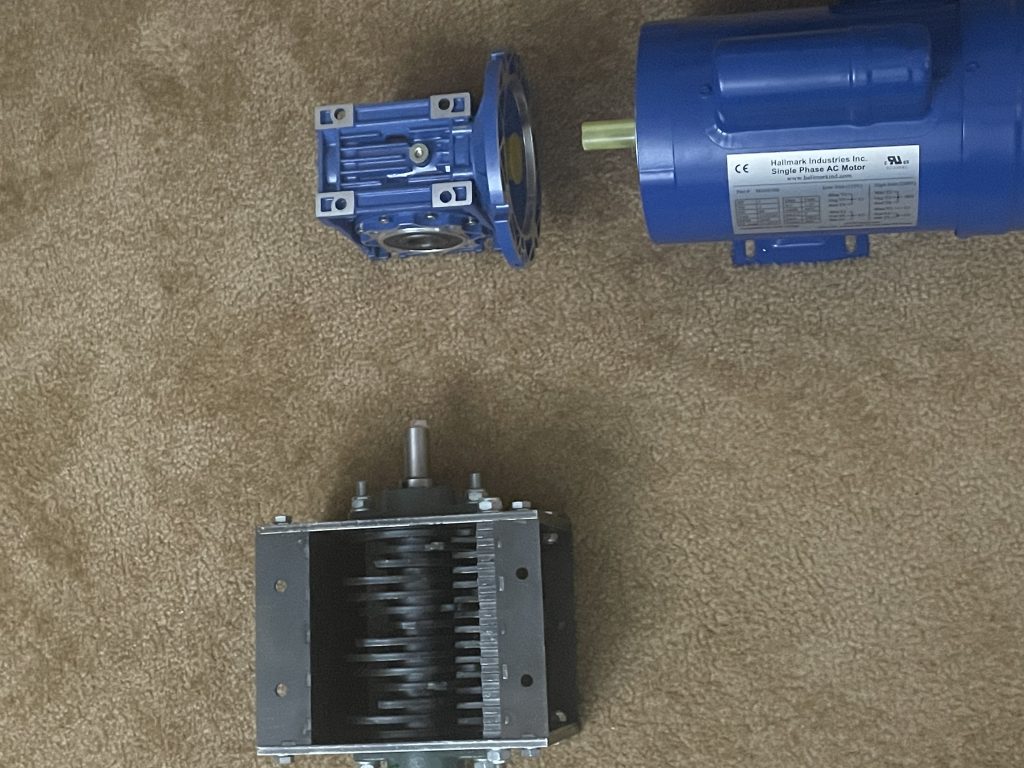

After the pandemic hit, the machine-making process has stalled. We’re storing the gearbox and motor at my place and I’ve worked on pieces to put the machine together, but the lack of a workplace and tools has made it difficult to coordinate the construction process. As if that was not enough, being students, our schoolwork has kept us from putting more effort into our project.

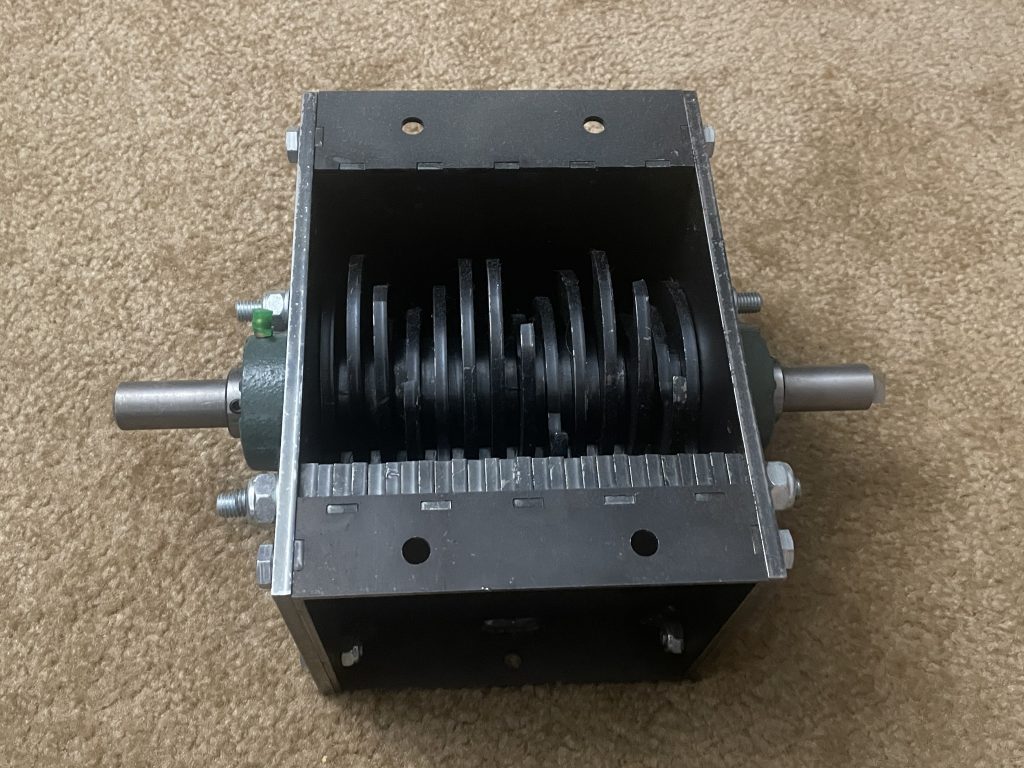

But we have made progress. We realized that a shredder blade-box may be more cheaper to order than build ourselves, and the entire process would also take work that we can’t do. We ended up ordering a shredder box from the precious plastic bazaar.

The shaft of the motor and gearbox are already compatible, but the gearbox and the blade box are not. Currently, I’m working on 3D-printing a part to adapt the shaft from the motor to the blade-box so that we can properly order a piece that would properly withstand the axel’s spin. If the piece somehow actually withstands this spin, we’ll continue using it until it breaks.

The machine-making process will be an especially difficult one, but we’ll be doing our best to make progress. The sooner we get to school, the faster this project will approach completion.

-Michael